Build.It.Better

Build.It.Better – with EcoBlox

Colorado Earth is supporting the families that lost their homes to fire in the Town of Superior. The page is dedicated to providing information about our services.

Fires are on the Rise

Sadly, we are seeing an increase in fires destroying communities around the nation. Traditional wood frame construction does not protect people and their belongings in the event of a fire, yet we continue to build this way.

High Embodied Carbon Building Materials

The production of concrete generates 8% of global warming emissions. If concrete were a country, it would be the third largest emitter after the United States and China.*

Colorado Earth is currently conducting a Life Cycle Assessment (LCA) to understand the carbon footprint from cradle to gate of our lime-stabilized EcoBlox.

*Source: King, Bruce, Build Beyond Zero, 2022

Supply Chain

One thing we are quickly learning is that resources are becoming difficult and more costly to acquire. Locally-acquired materials provide the customer with a greater sense of assurance, require less transportation, and reduce the overall carbon footprint.

Longevity and Human Health

Studies show the average lifespan of a home is about 50 years. Many of these homes experience water damage, which includes water vapor in the air. A humid environment can cause metal to rust and wood to rot, as well as issues with our health. Earthen masonry provides an optimal indoors relative humidity and EcoBlox have a pH in which mold cannot grow.

Thermal Mass and R-value

We often receive the question “What’s the R-value of an EcoBlox?”

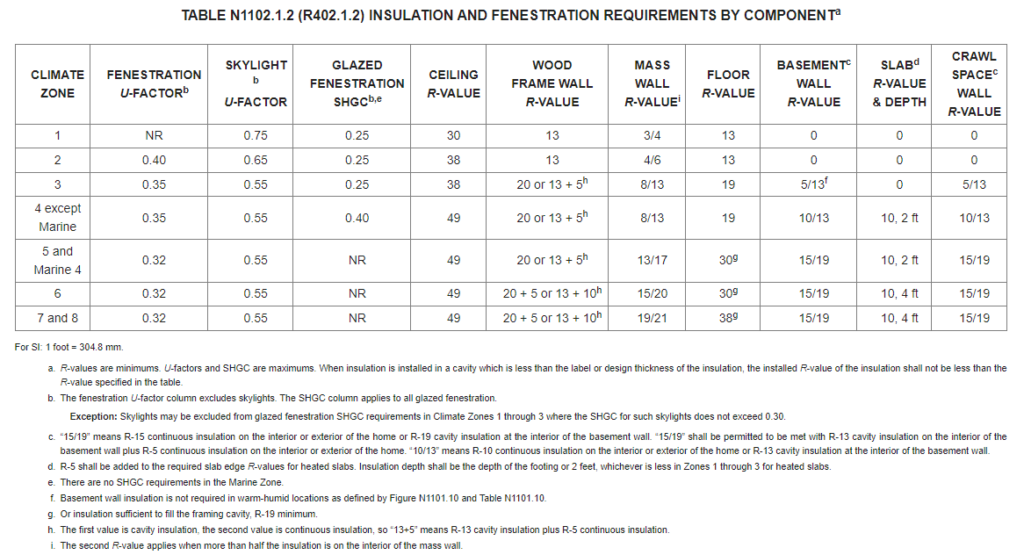

The R-value of an EcoBlox is roughly 0.42 per inch. But there’s more to it when trying to understand the thermal performance of a wall assembly in the building envelope.

R-value is a measurement of a material’s resistance to heat flow and the greater the R-value the less heat flows across the material. U-factor is the reciprocal of R-value and is a measure of the heat transfer in a material. A lower U-factor means less heat flows across a material. Units for R-value in the U.S. are hour-ft3-deg F per Btu. This means that the heat loss per hour across a wall is a function of the R-value, the area of the wall, and the temperature differential across the wall.

EcoBlox, and the majority of masonry walls, have the ability to store significant amounts of heat when in contact with direct solar gain. Due to the greater weight when compared to traditional wood frame construction, masonry walls tend to release this heat slowly which in turn reduces the peak energy demand for heating. A similar effect can be observed in climates where energy is primarily used for cooling. The effect of this heat storage is the thermal equivalent of a mechanical flywheel – it evens out building energy requirements.

An inconsistency arises when predicting energy usage using only R-value. R-value does not account for the stored or released energy inherent to mass wall construction. Previous attempts have been made to provide a modification factor for the R-value to incorporate this effect. The M-factor was introduced as a result of research conducted in the 1970’s that indicated heavy masonry walls had an effectively higher R-value in most climate zones. The M-factor served well for nearly 20 years until new energy codes were developed in the U.S.

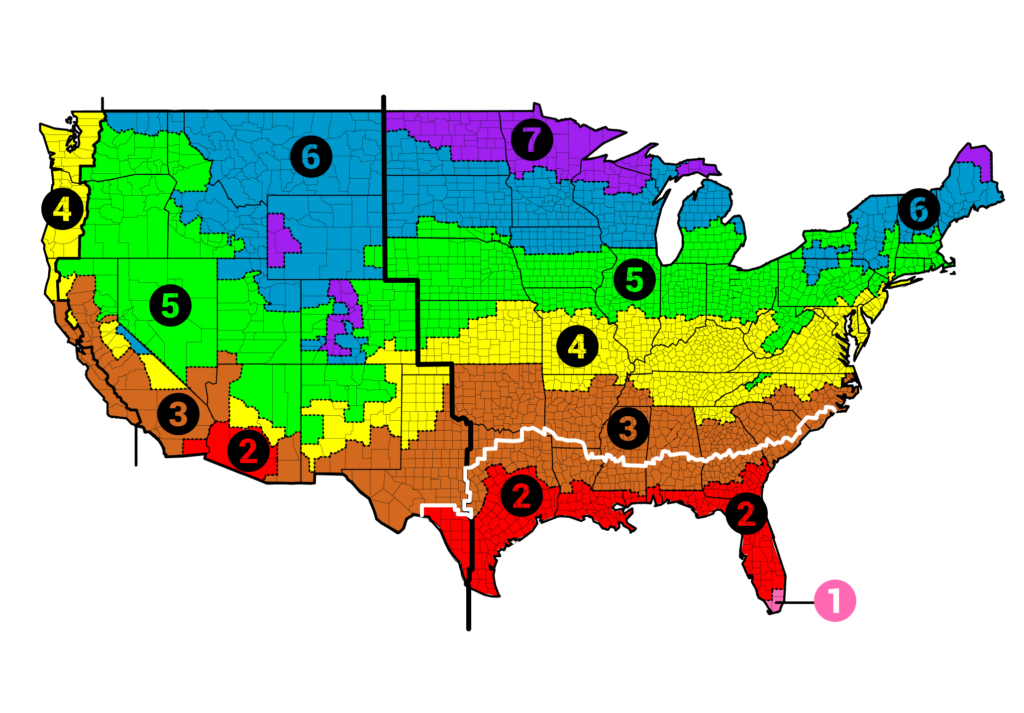

Today, nearly all new structures must comply with energy code requirements. The current method of recognizing the effect of thermal mass is reflected in the energy code requirements by specifying minimum R-values for mass walls separately from those listed for wood-framed walls.

Reference: Thermal Advantages of Masonry Walls, David Woodham, P.E. Atkinson-Noland & Associates, Inc

How Colorado Earth is Supporting Mass Wall Construction and Thermal Performance Values

Colorado Earth and Lisa Morey has been selected by the Department of Energy to work with the National Renewable Energy Laboratory (NREL) in Golden, Colorado.

The research will involve a thermal performance analysis of thermal mass using lime-stabilized compressed earth blocks, or EcoBlox, and a joint venture with Syndego on their wax-free, patented Phase Change Material (PCM) reflective blanket. Both products have the ability to reduce peak energy demands, reduce the need for high embodied energy insulation, and balance out our thermal fly-wheel effect to create stable temperatures for indoor living environments.

The study intends to expand upon the current platform of determining energy efficiency in a building. The current energy code is based on a thermal resistance compliance, however the use of thermal mass and PCMs should be able to reduce the demand by controlling peak temperatures.

For more information about this study please visit https://www.nrel.gov/west-gate/cohort-2.html